Eng Refresh, Health Check, etc 16

by , 24-01-2015 at 01:59 PM (1941 Views)

Checked existing valve clearance and although I didn't warm up the garage enough today, they were way too tight. Only one of the exh valve at Cyl #1 and both exh valves at Cyl #2 were within the spec. Rest of them were all too tight but by very consistent amount. Didn't see noticeable difference at Cyl #3, 4, 5 that consistently showed about 10psi lower figure from other cyl for the compression check.

During the re-assembly process and 4Hr marathon valve clearance session, I normally keep the room temperature stable so let's see how it goes.

Started the inspection around the inside of the engine.

Despite the excessive amount of liquid gasket used, it was not applied properly that it allowed oil seepage at many places.

The white liquid gasket from the factory was not removed and also the mating surface was not degreased well that the black liquid gasket was not doing good job.

You should not see oil around this bolt.

The reason why I saw so much oil at the front bank before removing the valve cover.......

Despite the higher temperature through the track session and also considering the mileage covered, the potting at the CRK/CYL sensor is in very good condition.

No need to replace it on this engine.

Need to wash off the seeped eng oil behind it though.....

The seeped oil at the rear bank was not too bad compared to other engines. On this engine, for some reason, it looks like the seepage was from the intake side.

Lots of people struggle to install the valve cover gasket properly at the rear bank due to limited space and you have to turn the cover 90deg during the installation if the eng was kept isndie the bay.

As there is no check marking on all of the bolt heads, it is possible that this WP was replaced in the past. However, looks like the bolts were not tightened to the spec, not tightened in several rounds, didn't think about the tightening sequence or simply didn't re-surface the mating surface of WP gasket that it allowed the coolant to leak.

There were some markings on the TB and while I think it's more likely to be the liquid gasket, oil and melted potting, it could be the trace of coolant as well.

I always replace WP at the time of Eng Refresh so interesting to see how it was installed previously.

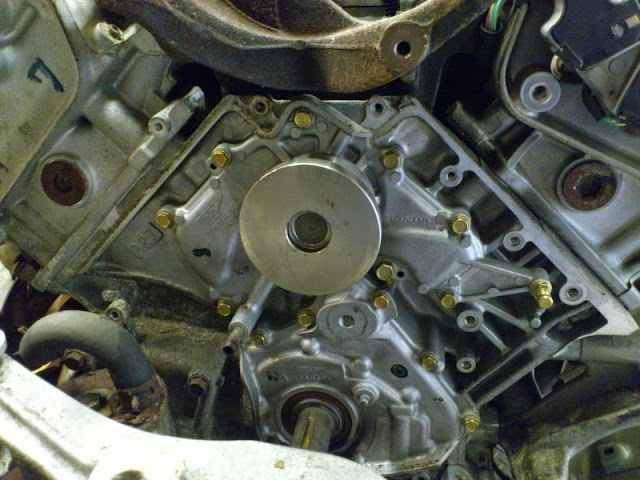

I don't think it's leaking but after seeing this, I think I have no option but to replace the crank seal on this engine.

The thrust movement of the crank is minimum so that's a good news.

Cleaned the area behind the crank pulley to this level. It was covered in thick oil/sand/gunk debris.

Had fun removing the bolt at the base of oil level gauge pipe..... From time to time, I had the same issue in removing this bolt as it can easily get moisture/heat and enough oxygen.

Email Blog Entry

Email Blog Entry