Eng Refresh 15

by , 27-04-2014 at 12:37 PM (6395 Views)

As same as the cyl head, checked the deck (eng block) with straight edge.

As it has higher tolerance and because of its size/shape, very unlikely to show

issues but needs to be checked.

Used vacuum pump to remove as much debris/black oil out of the thread on the

eng block and cleaned each holes thoroughly.

Then used new head bolt to check for any un-even resistance at each holes.

This is very important as it will cause squeaking noise while tightening the

head bolts later resulting in incorrect torque.

New o-rings at the oil orifices after cleaning them.

Had to spend some time cleaning the surface of rear exh manifold port

where the gasket sits.

It was covered in oxidation so looked like it was not sealed properly.

New head bolts.

Unlike some of the head bolts using the dial gauge for torque control past the

stretch point (donít know the exact phrase in English...),

NSX engine uses just torque figure and itís before reaching its stretch point so

it can be re-used.

However, as this engine showed issue during block check and since they are not

that expensive, I normally just replace all of them with new ones.

New head gasket on the deck.

Rear head installed.

It was dirty but not too bad cleaning this side compared to the front one.

I normally use the digital torque wrench but for the area such as head and

crank, I prefer using the old method with big dial for the ease of

torque control.

There are lots of famous tool manufactures in the world but for the

high accuracy torque wrench, I trust the one from Tohnichi.

They only make high accuracy measurement instruments.

Can't remember the price but not cheap....

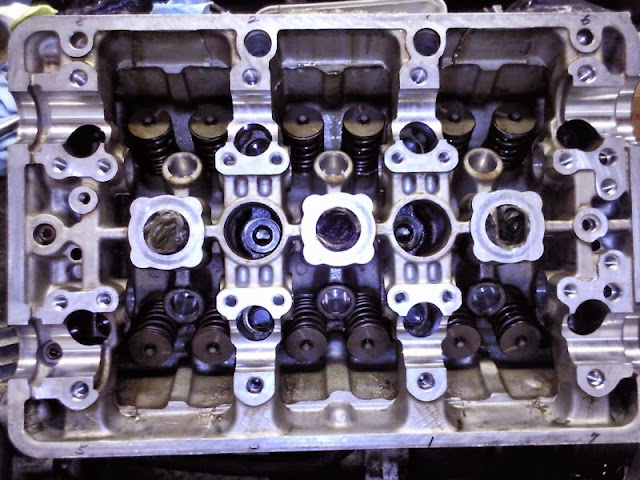

Front head installed.

Took ages to clean it to this level and still there are some solid black gunk left

but canít do much unless soaking the head in the hot cleaning liquid.

Iíll leave the rest to the hot eng oil while the engine is running.

Now Iím going to leave the heads overnight without touching anything before

carrying out the final torque check of the head bolts.

In the meantime, still cleaning the black contaminated rocker arms.

It stinks with blowby and it will be even worse when I start using lots of

assembly paste.

Hope to start the rebuild process from Monday.

More to follow later.

Kaz

Email Blog Entry

Email Blog Entry