Main Relay

by , 25-03-2014 at 11:15 PM (3417 Views)

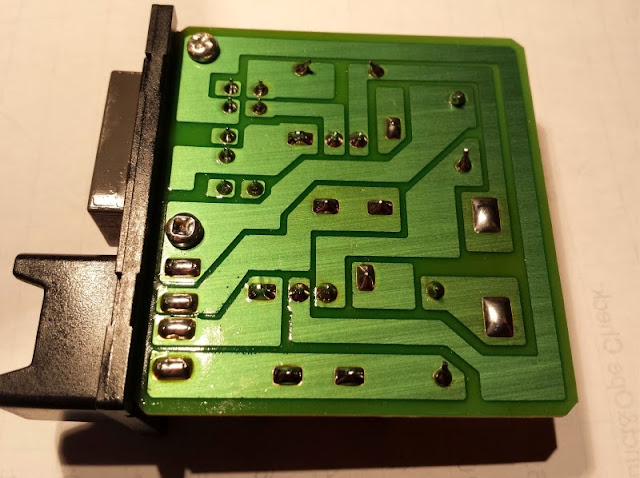

Another owner sent in his old Main Relay for re-soldering.

He bought new one from me several years ago and just wanted to

have backup for emergency usage.

The mechanical relays inside the old one were from WK23-26 of 1991 so

they were the old spec with mechanical spring.

The later spec has metal plate spring instead.

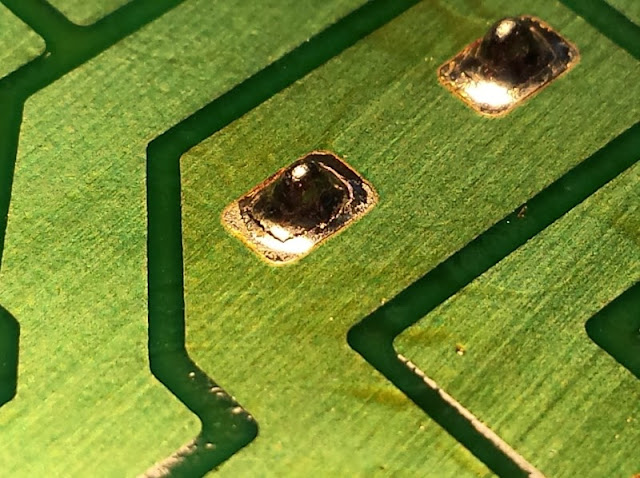

The famous soldering crack at several joints.

Itís triggered by several factors such as the size of the through hole,

circuit board material, amount of solder used, vibration, mounting method,

temperature, age, etc so you canít predict when it will happen.

This issue is not just specific for NSX but also happens on many other

Honda/Acura models.

For NSX, Honda didnít make any changes to the relay spec so even you

replace it with the new one, the same issue will happen eventually.

There were even several reports of replacement new relays failing

within just after 2 years!!

Re-soldering wonít fix all of the issues because there were several cases

reported with burnt relay contacts as well.

The internal relay capacity itself was not big enough under certain conditions.

Itís the same reason for the EPS controller with error code #22.

Re-soldered and cleaned all joints carefully.

If you just re-solder them without knowing the actual cause of the issue,

you will end up with solder just covering the surface with big air gap underneath.

Therefore, you need to re-solder it in specific way with proper temperature control.

Applied conformal coating for added protection and ready to be returned to the owner.

Kaz

Email Blog Entry

Email Blog Entry