Eng Refresh 11

by , 23-10-2013 at 11:47 AM (2648 Views)

Another catch up updating the blog....

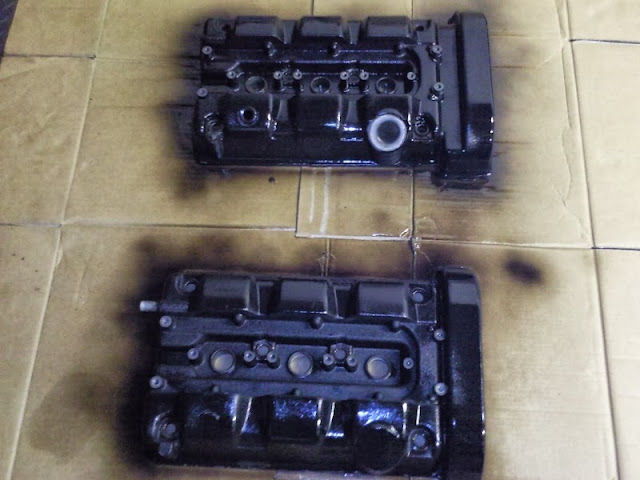

The original coating of the valve cover was already contaminated

at different level at many places.

Also, part of the coating was already missing exposing the magnesium.

Unless I strip it to the bare metal, it is not possible to get even finish.

I donít have enough knowledge or facility on how to treat magnesium before

painting and thatís beyond my service.

Itís better to send the valve cover to people with proper painting facility.

I think Andy at Vtecdirect has the experience and offer the service as seen here;

http://www.nsxcb.co.uk/showthread.php?10958-Cam-Covers

As my standard procedure for the black valve covers, just quick cosmetic touch up.

You wonít get even coating/finish but enough to make the engine bay looking nice.

New CYL/CRK sensor installed.

Another dreadful looking oil cooler.

I can remove some of the rusted layers with just my finger so

the rust has already managed to deeply penetrate through the

top section.

I was also surprised that the two coolant hoses at the oil cooler

managed to survive without bursting until now.

Looked to be never replaced and both of them were already fattened and

the hose clamps were already chewing into them.

Glad we can replace them before causing potential overheating condition.

Took ages for cleaning the oil cooler bracket.

Next time, if I were replacing the oil cooler, I will get new bracket even if

it can be re-used considering the time spent for cleaning and the state of

the oil pressure switch body as well.

Email Blog Entry

Email Blog Entry